The green thread

At Dekker, we believe in a future where sustainability is not just a goal, but a way of life. Our Green-thread-stories provide a glimpse into how we work step by step towards more responsible business practices concerning people, planet, and prosperity. From promoting people-centric HR practices to striving for eco-friendly production methods, our employees are the driving force behind our ongoing efforts to make a positive impact on the world around us.

Read here how our diverse teams collaborate on innovative solutions that not only reduce our company's ecological footprint but also contribute to the social and economic development of our communities. By working together and learning from each other, we are committed to a more sustainable future.

De groene draad

Bij Dekker geloven we in een toekomst waarin duurzaamheid niet alleen een doel is, maar een manier van leven. Onze Groene-Draad-Verhalen bieden een inkijkje in hoe wij stap voor stap werken aan een meer verantwoorde bedrijfsvoering op het gebied van people, planet en profit. Van het bevorderen van mensgerichte personeelspraktijken tot het streven naar milieuvriendelijke productiemethoden, onze medewerkers zijn de drijvende kracht achter onze voortdurende inspanningen om een positieve impact te hebben op de wereld om ons heen.

Lees hier hoe onze diverse medewerkers samenwerken aan innovatieve oplossingen die niet alleen de ecologische voetafdruk van ons bedrijf verminderen, maar ook bijdragen aan de sociale en economische ontwikkeling van onze gemeenschappen. Door samen te werken en te leren van elkaar, zetten we ons in voor een duurzamere toekomst.

Dennis Boevé / Maaike van Dijk

"Sustainable production really makes a difference when you're making around a 1,000 kitchen countertops per day."

Dekker has been committed to sustainability for many years, which Dennis Boevé and Maaike van Dijk have long been aware of. However, they are particularly proud of the major strides the company has made recently in producing sustainable kitchen countertops. 'Dekker is rapidly advancing towards sustainability.'

‘Did you know that Dekker has been using residual waste to heat the factory since the 1980s?’ Dennis says after the interview at Dekker’s headquarters in Zevenhuizen. Behind him, through a large window, you get a direct view into the factory hall of the kitchen countertop producer. Pipes run along the ceiling, carrying water heated by the energy generated from recycling the factory’s residual waste.

As production supervisor, Dennis can always be found in the factory hall where he manages about 70 employees. Together with his team, he ensures that over 1,000 kitchen countertops are produced daily. In addition, he collaborates with Maaike on addressing customer issues and implementing new or improved products within the production process. "For instance, when a customer requests an extra thick countertop, Dennis collaborates on how best to incorporate that into our production," explains the product manager. Maaike works daily at Dekker on enhancing and further developing the product assortment.

Greengridz

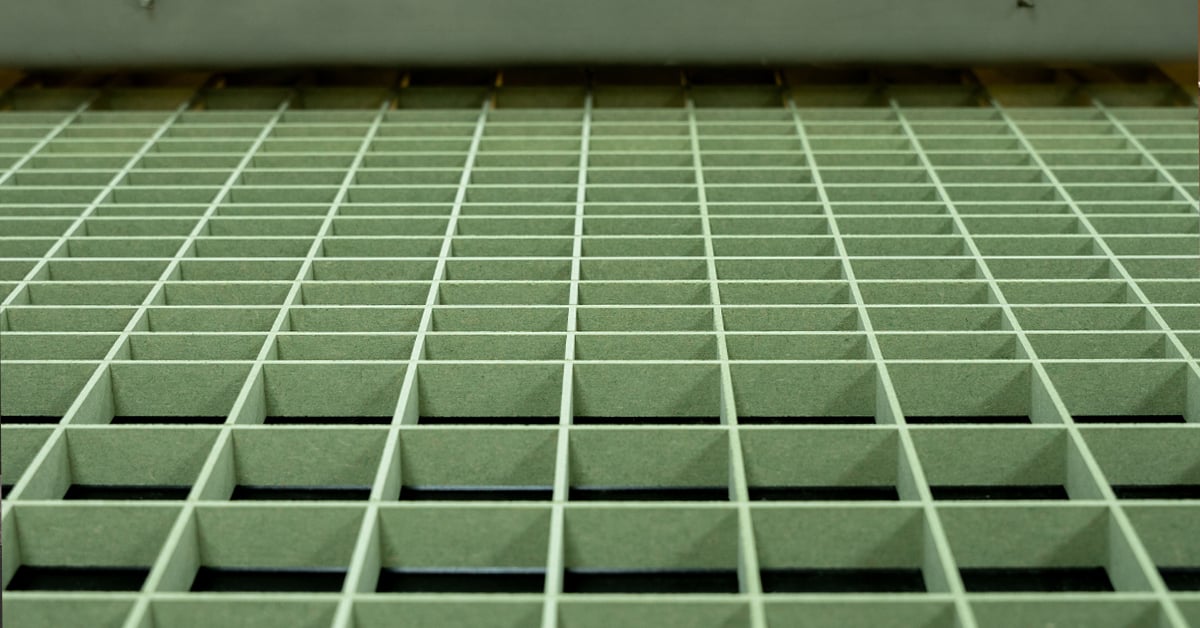

Dennis and Maaike have long noticed the increasing demand for sustainable products from customers. "In the project market, we saw over ten years ago that the government started imposing more sustainability requirements. Projects needed to become greener," Dennis explains. This led to a demand for kitchen countertops with a low environmental impact from Dekker's customers who supply kitchens for housing corporation projects. "Dekker responded by collaborating with suppliers to develop a lightweight kitchen countertop made from sustainable materials," Maaike adds. "This countertop consists of a honeycomb panel made entirely from FSC-certified wood, which we call Greengridz. Whereas we previously used plywood, we now use this material as the base for most of our kitchen countertops.

"With Greengridz, you save up to 60% of raw materials compared to plywood because the panel is made with a honeycomb structure," Dennis explains enthusiastically, grabbing two sample pieces from a table behind him: a piece of plywood and a piece of Greengridz. "Feel how much lighter Greengridz is compared to plywood." The fact that Greengridz is so much lighter is one of the reasons it is more sustainable than plywood. Maaike adds, "With Greengridz, we reduce CO₂ emissions by 60% because simply fewer raw materials are needed for production. This also means less energy is required for transport and manufacturing." The success of the material is also due to its functional advantages in addition to its environmental benefits, as it is more rigid, harder, and more water-resistant. To make the product even greener, Dekker is now working on upcycling Greengridz panels. The panels are converted into 100% activated carbon, which can be used in water and air filters.

Dreamteam

The fact that Greengridz is so much lighter is an added benefit for the installers who fit the kitchen countertops. This helped with the product's introduction, Dennis and Maaike noticed: "When introducing a new product to a customer, it’s very important to involve the installers in the process. The unfamiliar is often unappreciated." It took some time before everyone was enthusiastic about Greengridz, but now Dekker sells more Greengridz countertops than plywood. Maaike explains, "Dennis did a great job involving the installers by showing them that Greengridz is easier to work with than plywood." Dennis adds, "I let the installers experience how much nicer it is to work with panels that are three to four meters long and much lighter than plywood. When they felt the difference, you could see their faces light up." "This makes us a dream team," Maaike interjects. "I explain the theory, and Dennis complements it by demonstrating the practical benefits."

Maaike also wants to express how happy she is to work at Dekker. "We do everything we can to move full speed ahead towards sustainability as a company. As an employee, I'm quite proud of that." Dennis, who has been with Dekker for 30 years, completely agrees: "This world needs to last a lot longer. By guiding our customers towards sustainability, we're making a valuable contribution."

Mark de Waard

"Sustainable business means purchasing with impact. People should want sustainable kitchen countertops because they are more attractive and affordable."

As the procurement manager for the entire Dekker group, Mark de Waard observes that corporate social responsibility (CSR) is playing an increasingly important role in supplier relationships. He fully supports this direction. "In line with Dekker's motto, I would say: just do it!"

Previously, from Beuningen, Mark organised the procurement of materials for Topline Custom Countertops. Since Dekker acquired this company about four years ago, the procurement manager has been managing relationships with over 100 suppliers across the entire Dekker group. "I handle both the strategic and operational aspects of procurement," Mark explains from his new base in Zevenhuizen. The strategic side involves negotiating conditions and agreements under which suppliers deliver their products to Dekker. Mark adds, "Our CSR requirements also fall under this area." The operational side deals with ensuring inventory is maintained daily. Because, as Mark emphasises, "We always want to prevent disappointing our customers."

Seeing and hearing

As procurement manager, Mark experiences that CSR is playing an increasingly important role in procurement. "CSR has always been a topic when visiting our suppliers. But now, it's often one of the first items on the agenda," he explains. Dekker always requests information from suppliers regarding their CSR policies, internationally known as CSRD or ESG, as there is now ample attention and regulation within Europe as well. It also extends further into the supply chain, as Dekker's suppliers must demonstrate how they manage their suppliers and raw materials. Based on this information, Dekker engages in discussions with its suppliers and sets expectations. For Mark, company visits are essential in this process. "Seeing and hearing what happens on the factory floor at a supplier's site is crucial for me to gain a clear understanding."

A good example is the improvement of the production process at a supplier in Italy. Mark explains, "When we visited this factory, we noticed that the products were well produced, but the floor organisation was chaotic. We then reviewed the procedures and workflows with the supplier and made agreements. They even appointed someone responsible for these improvement processes at the supplier's site. Now, it's tidy and the production is much more thoughtful." He observes that this also makes it more sustainable. "For instance, there is significantly less production waste, and product rejection rates have decreased sharply."

Complex issues

However, expectations regarding CSR often present complex challenges for Mark and his colleagues. Dekker, for its granite countertops, is affiliated with TruStone: an initiative within the Dutch and Flemish natural stone sector. TruStone involves agreements among governments, businesses, NGOs, and unions aimed at promoting more responsible production and procurement of natural stone. Mark explains, "TruStone has asked us to verify whether our suppliers pay a living wage to their workers in the quarries. This is certainly a crucial aspect from a CSR perspective, but what constitutes a living wage in India? That in itself sparks an interesting discussion, and it's something we cannot easily determine. Moreover, how do you verify this? It requires finding parties with the expertise to report locally, reliably, and transparently. This straightforward question poses a significant challenge for our department."

Ideally, the procurement manager would prefer not to purchase granite at all, especially now that there are increasingly more sustainable alternatives available on the market. "But as a company, you must also consider the consequences of your decisions elsewhere in the production chain. People in quarries might lose their jobs if we make this decision," he outlines the dilemma he faces.

Just do it

Dekker can give a positive boost to sustainability in the market, according to Mark: "As a market leader, we also feel obligated to try to set the direction when it comes to the use of sustainable materials. Other parties often follow suit if a product proves successful." The motto of Dekker, 'just do it', also contributes to this, he experiences in his relationships with suppliers. Mark explains, "Dekker has many long-standing relationships with suppliers based on mutual trust. If suppliers need to invest in developing sustainable products, we as a stable partner are happy to join in. That's when we say, 'take action'. Often, you see them then take action because you have a better chance of success when you work together."

Niels Kölder

"We only make sustainability claims when we know exactly how it stands."

When he started working at Dekker almost a year ago, he wondered if he would need to persuade his colleagues to opt for sustainable products. Now, product engineer Niels Kölder realizes that this is not necessary at all. 'At Dekker, there is a strong motivation to invest in sustainability.'

Before joining Dekker, Niels worked at a small sustainable startup that sometimes struggled to stay afloat. 'Because it often made more financial sense, we had to increasingly opt for less sustainable solutions,' the product engineer explains one Wednesday morning at the headquarters of his new employer in Zevenhuizen. 'It's great to now work for a company that can afford to prioritise sustainability initiatives.' Initially, he was a bit hesitant: would he, as a product engineer, have to persuade his colleagues to choose sustainable products? He quickly noticed that this was not necessary at Dekker. 'Here, there is an intrinsic motivation to invest in sustainability.'

To measure is to know

As a product engineer at Dekker, Niels is involved in testing 13 materials used in the countertops the company produces. He tests, for example, whether they are prone to staining or scratch-resistant. He also maps out the sustainability aspects of the materials. Niels explains, 'We work based on a Life Cycle Analysis (LCA) of the material: this is a dossier that assesses how the material performs on various sustainability aspects such as CO₂ emissions, water usage, origin of raw materials, etc.' Dekker used to outsource the creation of LCAs to an external party but is now taking this process in-house. 'This allows us to have even better control over the sustainability aspects of our countertops,' Niels elaborates.

Because: To measure is to know. If a company truly wants to make sustainable claims, understanding the precise details is crucial, according to Dekker. Sometimes, initial assumptions are proven wrong in practice, as Niels explains. 'I've just discovered, through an LCA of one of our materials, that it's likely much more sustainable than we previously thought,' says the product engineer, clearly surprised. Measuring the sustainability aspects of materials also guides decisions towards sustainability. Niels elaborates, 'Perhaps our own LCAs will show that using a bio-resin or adhesive for our countertops could be a significant step forward.'

Determination to persevere

It's often not easy to bring a sustainable product to market, they know at Dekker. Sometimes, the company invests years in developing a new product only to decide at the end that it won't be launched after all. 'Sometimes a product may be environmentally sustainable but doesn't meet our standards for a countertop,' explains Niels. 'For instance, if the material isn't durable enough. Soon, the surface accumulates so many stains or scratches that the customer wants a replacement within two years. In the end, that's not sustainable either.'

But that doesn't mean Dekker throws in the towel. Within the company, they know that often you have to invest in many new products before you can finally bring one or two to market. Niels says, 'There are really very few companies willing to do this. I find it remarkable to see the determination within Dekker to continue on the path towards sustainability.

Karin Stuurman- Siegenaar

"To me, sustainability and inclusivity are inseparably connected to each other."

A sustainable business approach at Dekker primarily means investing in your people, according to HR manager Karin Stuurman-Siegenaar's experience. The effectiveness of this approach is reflected in the figures at the countertops manufacturer in Zevenhuizen. "Our employees have an average tenure of about 25 years."

For Karin, joining Dekker seven years ago as HR manager felt very welcoming. "At my previous employer, I faced increasing guidelines from the German headquarters for HR policies that didn't always align with the needs in the workplace. Here, I experience direct communication and have the freedom to collaborate on finding suitable solutions together. This approach suits me much better."

Suitable work for a lifetime

For a family business like Dekker, continuity is key. This entails caring for employees well and also expecting their commitment. How does Dekker do this? "By encouraging employees to have lifelong suitable work within the company," explains Karin, who focuses on promoting sustainable employee well-being at Dekker. We carefully assess the balance between workload and capacity. For example, when an employee developed Parkinson's disease, we worked together to find appropriate tasks so they could continue working for longer. "Parkinson's is a progressive illness. We looked for tasks suitable for this employee, enabling them to remain mentally and physically active for an extended period."

Trust

Caring for people. That's typical of Dekker, according to Karin. "You can also see it in our absence management. We handle this internally so that we can maintain good contact with an employee who is absent." The HR manager notices that people at Dekker appreciate the accessibility of her department. "People really know how to reach out to us and sometimes share very personal matters. That's a sign of trust."

Moreover, the figures show that investing in your employees pays off. Employees stay on the shop floor until retirement. "Employees typically stay with us for a long time, with a 25-year tenure being quite common," explains Karin. She believes this longevity is linked to the level of freedom and autonomy employees enjoy at Dekker. Karin says, "You're trusted to take responsibility yourself. This gives people a sense of freedom and autonomy, allowing them to grow with the company. It makes staying with Dekker attractive."

Employment for vulnerable groups

Providing employment opportunities for vulnerable groups is also part of Dekker's CSR policy. Karin recalls that Dekker already employed individuals with greater than average distance from the labor market before it became mandatory for companies. "There has always been a sense of community within Dekker. We've always had the mentality of helping local individuals who haven't had opportunities elsewhere or who have faced challenges to get back on track here at Dekker," she explains. Recently, individuals with distance from the labor market have been offered contracts as well. Karin aims to expand this initiative. "We're definitely going to dedicate more time to this initiative this year. It's incredibly rewarding to see someone who has faced various challenges finally thriving with us," she adds. Simply giving people opportunities to grow and demonstrate their worth—this benefits the company as well.